PWL BigBean bean harvester

The PWL BigBean is a modern, fully Polish-made bean harvester, designed for intensive, efficient operation on farms specializing in bean and legume cultivation. Its design, based entirely on domestically produced components, guarantees high-quality workmanship, full spare parts availability, and ease of service. It is the only harvester on the market with road approval , allowing legal and safe operation on public roads without additional permits. Compared to its popular competitor, the Colombo Double Master , the PWL BigBean offers unique advantages that make it an exceptionally attractive choice for farmers.

Key advantages and equipment

The machine was designed with comfort, efficiency, and reliability in mind. The PWL BigBean is equipped with a hydraulic braked axle , with the option of upgrading to a full pneumatic system. While specific Double Master IV/EVO versions have a robust chassis, the locally engineered BigBean offers better adaptation to European road conditions and transport requirements. The quick-folding feeder system significantly reduces the combine’s prep time and simplifies storage.

A set of sensors monitors key components for operational safety, minimizing the risk of failure and allowing the operator to react promptly. A large 3,000-liter tank ensures long-term operation without the need for frequent emptying.

The machine uses components from renowned manufacturers such as FAG and SANOK, ensuring durability of the chassis and long service life. The combine is equipped with 460/70R24 W15Lx24 tires, which provide adequate traction and stability, even on difficult terrain.

The recommended tractor power is 140 HP , with a minimum requirement of 90 HP.

A professional machine for demanding farms

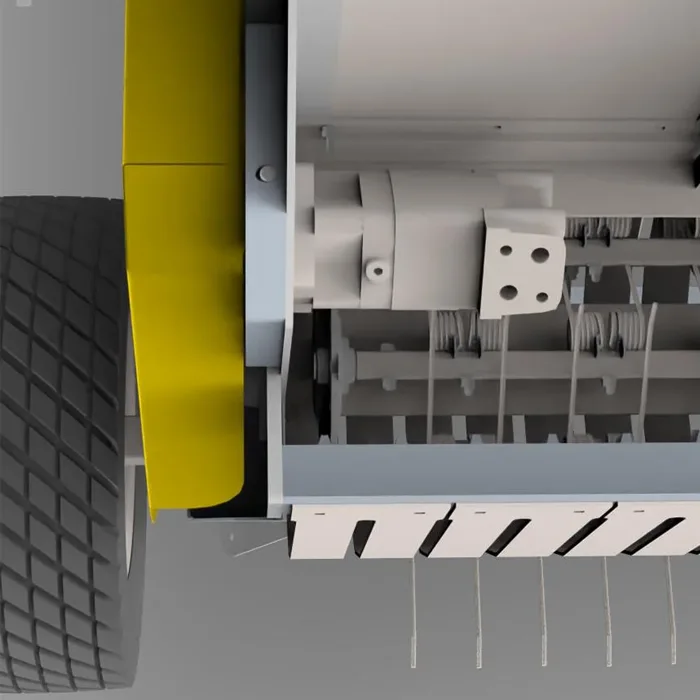

Pick-up

Reliable collection of plant mass

The pick-up is made of 6 mm or thicker steel, ensuring high durability and resistance to damage. Long, double tines efficiently feed the crop, and their quick replacement – thanks to easy rear access – minimizes service time.

Pickup speed can be adjusted directly from the operator’s cab, allowing the machine to adapt to current field conditions. The pick-up is hydraulically powered, with a maximum flow rate of up to 75 l/min, ensuring smooth operation and complete control. The Double Master also offers adjustable harvesting speed and threshing intensity, but the BigBean may be more intuitive for operators.

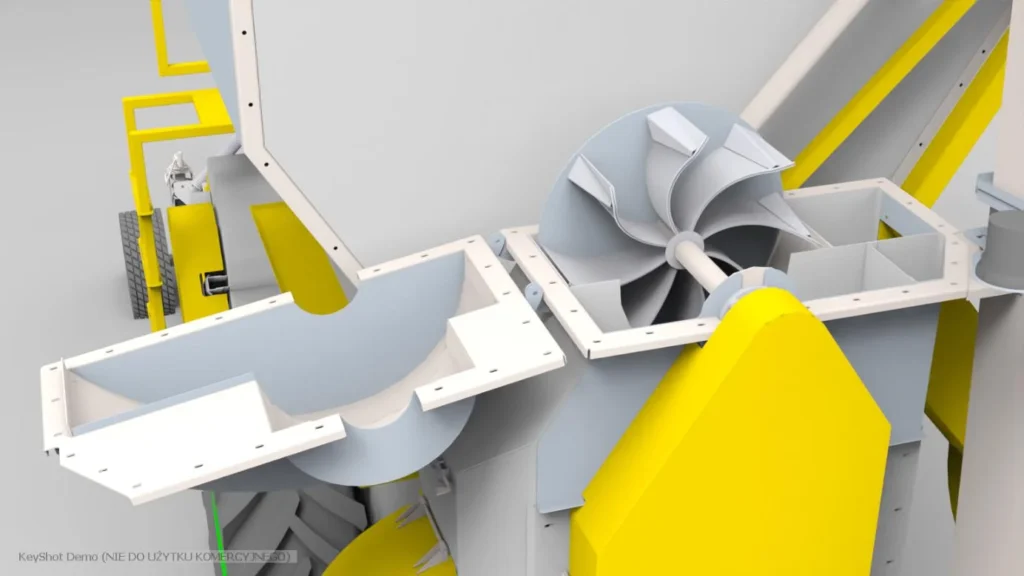

Fan

Efficient cleaning and durability

The fan is made of 6 mm thick, abrasion-resistant materials, ensuring durability even under heavy use. The design allows the operator easy access for servicing and quick component replacement if necessary.

ROTOR – the heart of the threshing process

The solid and precise rotor is responsible for effective threshing of beans.

The most important parameters:

- total length: 3490 mm

- auger length with discharge: 2680 mm

- pipe diameter: 250 mm

- outer diameter of the screw: 450 mm

- number of threshing fingers: 16 pcs.

The rotor is made of a uniform material along its entire length , eliminating bearing alignment issues—a common problem in competing machines like the Colombo Double Master. This ensures the BigBean runs smoothly, stably, and requires less frequent adjustments.

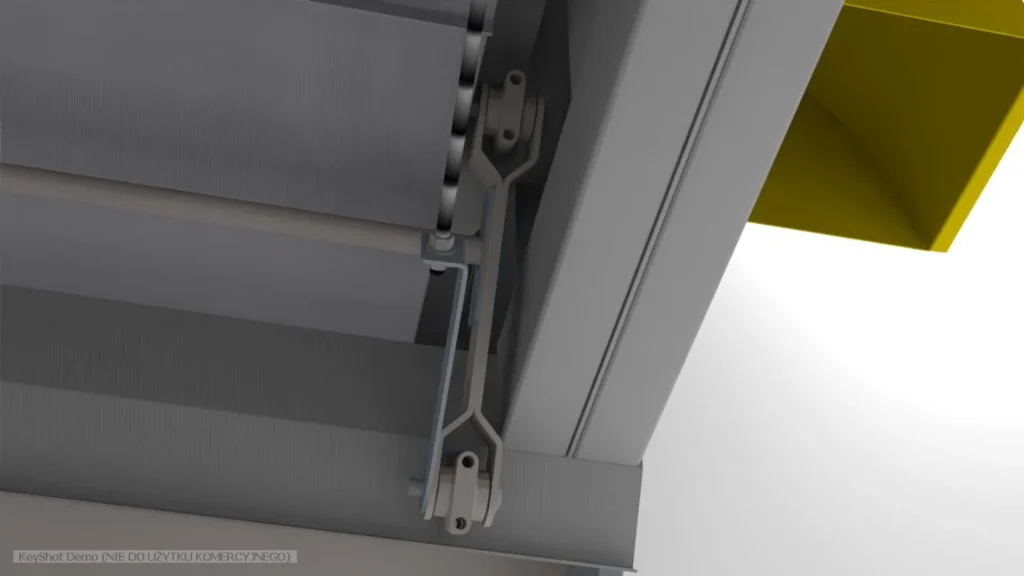

Threshing floor

Suitable for different bean varieties

The 1950 mm long, 627 mm diameter concave is available with mesh sizes from Ø21 to Ø25 mm, adjustable in 1 mm increments. Constructed from ST355 and Hardox 450 wear-resistant materials (6 mm thick), it provides wear resistance and long-lasting performance.

Additionally, the quick changeover system allows for rapid reconfiguration of the machine to work with different bean varieties or even peanuts. While the Double Master also offers adjustment options (e.g., changing sieves and separator systems), the quick BigBean system can significantly reduce machine changeover time and increase its practical versatility.

Grain pan

Precise separation of impurities

The grain pan is suspended on rubber-covered shock absorbers that dampen vibrations and stabilize the sieving system. The design allows for quick sieve replacement, allowing for easy adaptation of the machine to the type of material and desired cleaning effect.

Durable construction

Top-class materials

Only materials with high performance parameters were used in the production of the combine:

- main frame – S355 structural steel , resistant to heavy loads

- drawbar – bent sheets made of S420 steel, adapted to very high forces

- pins and bearing housings – 45H machine steel

- cover elements – S235 steel

- elements exposed to abrasion – Hardox 450 or materials of comparable strength

These selected materials guarantee failure-free operation even in the most difficult conditions.

Technical parameters

The most important information

- width: 3220 mm

- length: 6840 mm

- height: 4000 mm

- wheelbase: 1900 mm

- outer wheel track: 2310 mm

- weight: 4400 kg